Minimum cycle times with maximum flexibility and modularity! For the first time, the new transfer and bending technology will be presented in combination with the compression spring coiler FUL 26+.

The recently developed transfer and bending unit enables parallel forming operations over several stations and thus considerably reduces the cycle times per part. Stations are based on a modular concept that allows them to be adjusted to the most different applications and to be connected with the according spring, wire or tube bending machines. The transfer and bending unit will be presented at the wire show in combination with the spring coiling machine FUL 26+ for the production of extended loop springs that are often used in the automotive and e-mobility sector.

Productivity leaps with high-speed technology for the production of springs and wire parts

The 4speed technology celebrates its international world premiere. At WAFIOS, the name "4speed" has recently come to stand for machine developments that have been designed for highest production outputs. The new FUL 26+ 4speed and FUL 36+ 4speed are – in their ultimate expansion stage – the fastest spring coiling machines in the world. They produce compression springs at a wire infeed speed of up to 600 m/min.

The new high-speed wire bending machines will make their international trade fair debut in Düsseldorf and set new standards in terms of speed, productivity and quality. The WAFIOS BM 43 HS will be exhibited as a stand-alone machine and the BM 36 HS will be presented for the first time together with a handling robot that is fully integrated in the WAFIOS control system WPS 3.2 EasyWay.

Trendsetting: Coldforming of up to 22 mm high-strength spring steel wire – International world premiere of the FUL 226

With the new FUL 226 it is now possible to cold-form 22 mm wire at 2,000 N/mm². All the familiar cold-forming advantages known from FUL machines, like more freedom of geometry, the use of camera technology, and flexible programming possibilities, for example, are now also available for the upper wire diameter range. New markets are being targeted in the e-mobility, hybrid vehicle, and light truck sectors. The 40-ton spring coiling machine will be presented digitally in Düsseldorf.

Automated production solutions from WAFIOS integrated in one programming system

WAFIOS will present new automation solutions, like loading units, feeding systems, and production cell solutions, for all fields of application. The programming system WPS 3.2 EasyWay stays a decisive step ahead by integrating previously independent systems, like a handling robot or other processing units, completely into the machine's control system. The wire bending machine BM 60 and the servo-electric header RU 60 from WAFIOS Tube Automation will show how this integration works. The combination of 60 tons of forming force and newly developed tool system offers new possibilities in the production of wire parts that require an endworking process on one of their ends.

Future technology e-mobility for the first time at wire

The company will exhibit the FMU 40 E, with a handling robot completely integrated in the machine's control system, for the production of stator hairpins. Other applications, such as busbars and cooling lines used in the e-mobility industry, can be found at all WAFIOS booths in Düsseldorf.

Keeping maintenance processes intelligently under control – "Digital Services" by WAFIOS

WAFIOS' intelligent maintenance software "connectavo – The digital assistant for machines and machinery systems" will make its debut at the trade fair. WAFIOS is also presenting for the first time a standardized, open system for the complete networking of machines and machinery systems: the IoT Suite.

Numerous other machine premieres in Düsseldorf – WAFIOS presents the most extensive exhibition program yet

WAFIOS G450 spring end grinding machine with new robot feeding system. A Smart Machine connected with the trendsetting technology database iQsmartgrind and a new loading unit. Consistent expansion of the product families in all machine areas: The WAFIOS SNA 26 for the production of wave springs and rings closes the gap in the wire diameter ranges of the SNA 16 and SNA 36. After the successful market introduction of the already legendary ZO series in 2021, WAFIOS finally presents the long-awaited ZO 16 for smaller wire diameters. WAFIOS BMS 50 multiple-head wire bending machine for wire diameters up to 10 mm will also debut at the fair. The BMS will be exhibited together with a CNC-controlled chamfering device for chamfering both ends of rods.

From the straightening area, the WAFIOS straightening machine R 36 for straightening smooth rods will be presented together with iQmstraight for measuring the straightness of rods. It features a newly developed, adjustable rotor for automatic readjustment when processing rods that are not within the straightness tolerance.

Attractive service offers and innovative tool solutions complete the broad exhibition program

The new retrofit solution for the classic FMU 2 machine will also debut at the fair. From the wire bending area, WAFIOS presents the new, modular set of tools MBS for the most diverse applications. From the spring coiling area, the focus will be on new coating solutions for tools of the FUL series.

WAFIOS Umformtechnik presents PTS, the new "Pneumatic Transport System" on the cold former HC 4-15

The newly developed PTS ensures resource-conserving ejection of parts, meaning mixing of parts during product changes is effectively avoided. Parts leave the machine already in their correct position and virtually free from oil. Good parts are automatically separated from bad parts using a sorting switch.

EWMenn, the specialist for thread and profile rolling machines will present their new, digital machine assistant

iQ–Set-Up Assist: The easy-to-use and product-specific set-up aid that can be operated at the push of a button; and iQ – OEE Monitor: The machine data acquisition assistant for process evaluation. From their current range of machines, EWMenn will present the AF 141 high-speed thread and profile rolling machines with flat dies.

The theme of "Future Forming Technology" is also reflected in the program at the WAFIOS Tube booth

A revolutionary production technique for the flexible bending of large and small batches of plastic tubes opens up new fields of application – World premiere of the WAFIOS HotBend 35. The new RU 12 compact from WAFIOS Tube Automation ensures maximum flexibility in tube end forming operations. End forming operations with short cycle times – The machine will be exhibited at the show for flexible use, both as a standalone and cell solution.

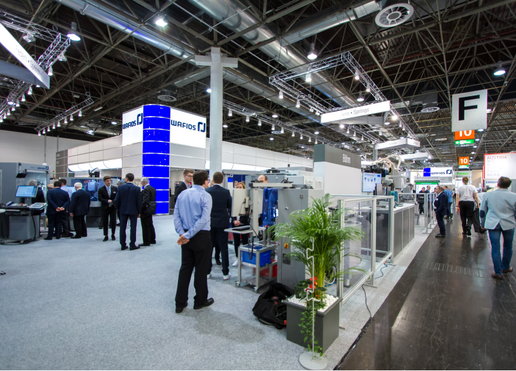

Visit WAFIOS at wire & Tube in Düsseldorf from June 20–24, 2022, Hall 10, Booth F 22/40 and Hall 5, Booth A21/A22. For our complete exhibition program under the motto of "Future Forming Technology" go to www.wireandtube.wafios.com. Arrange a meeting with us at the trade fair online today.