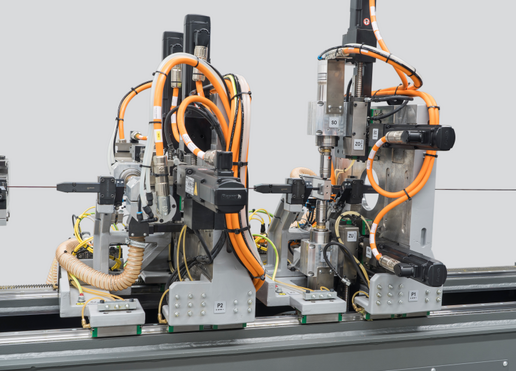

New and highly flexible bending concept

The SpeedFormer is the first machine that unites three proven bending techniques from conventional wire and tube bending machines in one unique system. One of the bending techniques has been used for decades in WAFIOS CNC spring and wire forming machines and has now been modified and optimized for the bending of hairpins. This technique is used for simple hairpin bends and enables the highest production speeds. A new, patented bending technique has been developed, based on the rotary-draw bending technique for tubes. It is used for making complicated bends with overlapping geometry elements as they occur at the head of hairpins ("S shapes"). This new technique enables the highest bending qualities and continuous process reliability as the processed material is clamped actively during the bending process, ensuring highest bending accuracy even when processing inconstant materials. In the "twisting" process – the third of the three bending techniques – the feed unit is rotated in such a way that a defined twist of the hairpin legs can be produced. This is essential for the precise fit of the hairpins in the stator and for a perfect manufacture of the electric motor.

Reliable operation from prototyping to series production – Identical bending process on the prototype and series production line

The manufacturing principle of the prototype production is transferred one-to-one to large-scale production. Therefore, there are no risks in the transition from prototype production to series production. The SpeedFormer reduces series production cycle times from 6–10 seconds per hairpin to 1–1.3 seconds per hairpin. Identical production technologies, i.e. the same tools and bending techniques, are used in series production. As a result, series production can be started up smoothly, as the prototype production line can compensate any bottlenecks or adjustments through parallel production. The tools, their programming and movements, of the prototype production line are identical to the tools of the SpeedFormer. Parts that have been approved on the prototype production line can be produced with the same kinematics on the series production line. As all tool data and programs can be transferred, the workload and risk in the start-up phase of series production are reduced to a minimum.

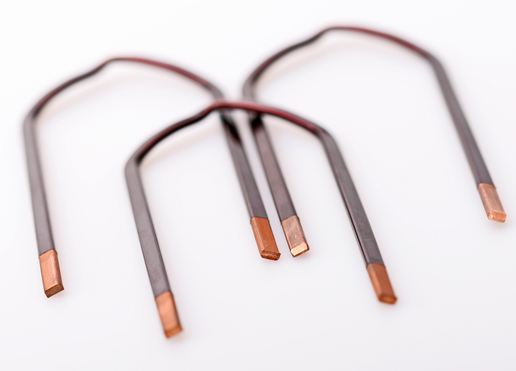

Highly flexible production of different hairpin geometries with intuitive operation

The different hairpin geometries of the stator can be produced with only one set of tools because the three-dimensional bending process is carried out without shape-dependent tools. Compared to the conventional hairpin manufacturing process by pressing, this freedom of geometry enables the economical production of different hairpin variants on the SpeedFormer. As there is no need to change any tools and as the production is CNC-controlled, batch size 1 production can be realized at full production speed. Another special feature of the machine is that the hairpins are programmed based on their geometry. This means that the operator enters the bending angle, the leg length and the twisting angle into a simple table in the order specified by the geometry of the hairpin. Based on this table, the system calculates the axis movements fully automatically in the background and in real time. This not only facilitates the production of new hairpins, but also allows quick corrections, e.g., during the initial set-up.

Extremely high process reliability and consistently good quality

CNC-controlled bending movements ensure a high level of process reliability. In any forming process, fluctuations in the material properties or geometries of the copper wire or coating can affect the geometries produced. Due to the CNC bending processes used by the SpeedFormer, bending angles and bending positions can be corrected by the software at any time. In combination with the camera monitoring system, an in-process control of the bending operations is possible. This distinguishes the SpeedFormer significantly from conventional machines that use shape-dependent tools.

Reduced material changing times increase the total output thanks to an automated straightening system

A production line with two separate pay-off units enables a rapid change of wire coils without an interruption of the production process. The wire coil is pre-adjusted on the pay-off unit system, which can be swiveled in. This reduces the machinery system's downtime to a minimum. The straightening process of the source material is another time consuming process. Depending on the operator's experience and the material's quality, a lot of time is required to set up the straightening system. Furthermore, a lot of source material is used up unnecessarily. With the automatic WAFIOS straightening system, the straightening device is automatically adjusted to a new wire coil.

Material fluctuations within the wire coil are not compensated.

The system increases the straightening quality and straightness of the enameled copper wire without requiring any intervention by the operator. At the same time, set-up times for material changes are reduced.

All in all, the WAFIOS SpeedFormer is a cost-effective and safe investment in the long term. It meets the high quality requirements of the automotive industry, such as high output, small space requirements, flexible hairpin geometries, simple transfer of prototypes to series production, low tool costs, high quality, and production reliability, for example. The SpeedFormer can be seamlessly integrated into the overall stator production system.