Machine comparison KBA

Our Accomplishments for Your Benefit

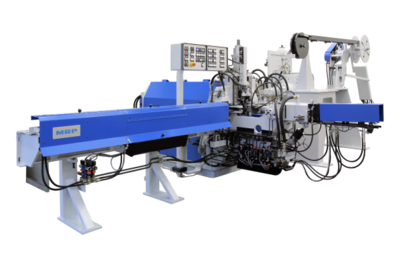

- Sophisticated design, i.e. the KBA 601 and its predecessors haven been successfully on the market for decades

- Fully automatic bending of chains

- Inductive or conductive heating of blanks can be provided by WAFIOS.

Please select wire diameter [mm]

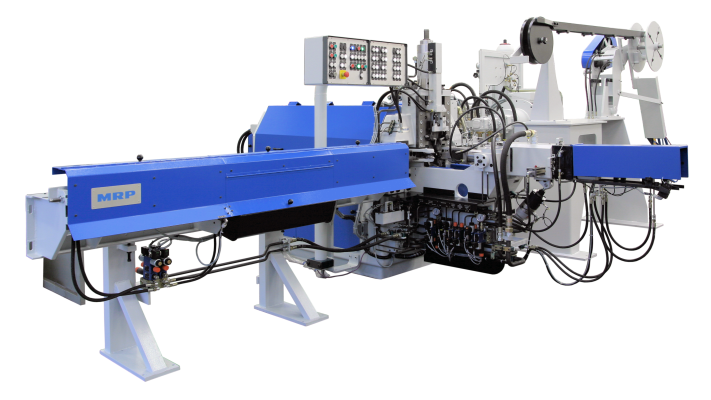

KBA 601

- Sophisticated design, i.e. the KBA 601 and its predecessors haven been successfully on the market for decades

- Fully automatic hot and cold bending of chains

- Inductive or conductive heating of blanks can be provided by WAFIOS.