Powerful Solutions for Electric Drives

Hairpins are bent parts made of insulated, enameled copper wire. They are used in the modern electric motors found in electric cars, hybrid vehicles, and e-bikes, where they replace the wound inductor coils that are part of conventional stators. Hairpin motors improve the power-to-weight ratio due to the packing density of the profile material.

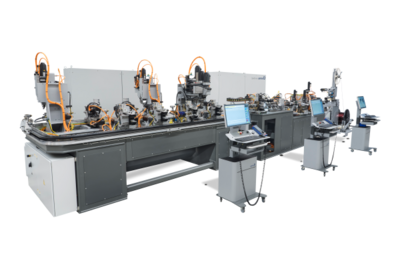

WAFIOS offers state-of-the-art bending technology for producing hairpins, covering everything from small batches up to high volumes.

Machines

Machine comparison FMU E

- Unique machine concept for producing hairpins and stator connection assemblies, and for expanding the FMU series in the field of e-mobility

- Bending process simulation opens up new possibilities, especially with regard to feasibility or collision monitoring

- Patented hairpin tool system combines active rotary-draw bending with the agility of conventional wire bending tools, prevents the material from slipping, and increases the quality of complicated geometries

- Newly developed feed unit prevents deformations in the profiled material and – together with the patented tool system – enables positioning of end legs

- WPS 3.2 EasyWay programming system offers easy, geometric programming and a clearly arranged overview of the materials and tools used

- The FMU E series can be complemented by insulation stripping, burr-optimized cutting and chamfering modules.

Please select smallest profile cross section [mm²]

FMU 40 E

FMU E – revolutionary rotary-draw bending process for hairpin production

This flexible new process means that the majority of hairpin geometries for a stator, including the stator connector parts required, can be manufactured in any sequence without the need to change tools. The patent-pending bending process enables bending work to be accurate and free of physical damage.

Outstanding flexibility with WPS 3.2 EasyWay programming system

Flexibility depends on the geometric programming of bending parts and/or hairpins. The geometric programming dispenses with the need for the user to program individual CNC axes. This speeds up the definition of hairpin geometries. The WAFIOS WPS 3.2 EasyWay control unit also allows you to import 3D geometries automatically with STEP / IGES files. After the coordinates have been imported, the required bending program can be produced automatically.