High-precision, powerful, and profitable

Our range of tube bending machines accommodating all requirements from 0.5 to 60 mm, with robot bending systems for everything from highly complex bending tasks to conventional tube forming. This high-end range of machines provides an economical way to fulfill even the strictest of demands.

Machines

Machine comparison BMZ Series

- Maximum degree of geometry with different bending sequences and tools

- High level of flexibility and high degree of automation

- Unique machine concept with special production sequences and integrated handling of workpieces

- Highest output and quality

- Configuration of machine according to product requirements

- Optimized for fluid lines required in the automotive industry

Please select tube diameter []

BMZ 6

| Tube diameter | 0.5 - 6.35 mm |

| Standard lengths, recommended | 500 - 1500 mm with regrabbing |

| CNC axes | |

| Standard/Maximum | 6 / 10 |

| Bending head | 2 axes |

| Spindle unit (without swiveling) | 2 axes |

| Lateral displacement of bending head | 1 axis |

| Internal mandrel unit | 1 axis (option) |

| Auxiliary gripper | Pneumatic |

| Swivel angle of gripper | 1 axis (option) |

| Gripper tool | |

| Operating principle | Pneumatic |

| Structure | Open |

| Single stroke | 500 mm |

| Multiple stroke | At will |

| Programming | |

| Length/angle | Yes |

| Coordinates | Yes |

| Job order lists | Yes |

| Graphical display | Yes |

| Automation | |

| Loading from a magazine | Standard |

| Position-oriented discharge | Standard |

| Combination with robots | Option |

| Weight | 800 kg |

| Space requirements | 1,600 x 800 x 1,350 (lxwxh in mm) |

BMZ 8

from 2

to 8 mm

| Tube diameter | 2 - 8 mm |

| Standard lengths, recommended | 2,000 mm |

| From BMZ magazine | 100 - 2000 mm |

| CNC axes | |

| Standard/Maximum | 6 / 10 |

| Bending head | 3 axes |

| Spindle unit (without swiveling) | 2 axes |

| Lateral displacement of bending head | 1 axis (option) |

| Internal mandrel unit | ---- |

| Internal mandrel unit | ---- |

| Auxiliary gripper | Pneumatic |

| Tube gripper device | 1 axis (option) |

| Swiveling in (spindle) | 1 axis (option) |

| Gripper tool | |

| Operating principle | Pneumatic |

| Structure | Open |

| Single stroke | 750 mm |

| Multiple stroke | At will |

| Programming | |

| Length/angle | Yes |

| Coordinates | Yes |

| Job order lists | Yes |

| Graphical display | Yes |

| Automation | |

| Loading from a magazine | Option |

| Position-oriented discharge | Option |

| Combination with robots | Option |

| Weight | 1,150 kg |

| Space requirements | 2,100 x 1,250 x 2,050 (lxwxh in mm) |

BMZ 12

from 2

to 12.7 mm

| Tube diameter | 2 - 12.7 mm |

| Standard lengths, recommended | 2,000 mm |

| From BMZ magazine | 100 - 2000 mm |

| CNC axes | |

| Standard/Maximum | 7 / 10 |

| Bending head | 3 axes |

| Spindle unit (without swiveling) | 2 axes |

| Lateral displacement of bending head | 1 axis |

| Internal mandrel unit | 1 axis (option) |

| Auxiliary gripper | Pneumatic |

| Swivel angle of gripper | 1 axis (option) |

| Gripper tool | |

| Operating principle | Pneumatic |

| Structure | Open |

| Single stroke | 750 mm |

| Multiple stroke | At will |

| Programming | |

| Length/angle | Yes |

| Coordinates | Yes |

| Job order lists | Yes |

| Graphical display | Yes |

| Automation | |

| Loading from a magazine | Standard |

| Position-oriented discharge | Standard |

| Combination with robots | Option |

| Weight | 1,950 kg |

| Space requirements | 2,150 x 1,250 x 2,050 (lxwxh in mm) |

BMZ 18

from 2

to 18 mm

| Tube diameter | 2 - 18 mm |

| Standard lengths, recommended | 2,000 mm |

| From BMZ magazine | 100 - 2000 mm |

| CNC axes | |

| Standard/Maximum | 7 / 9 |

| Bending head | 4 axes |

| Spindle unit (without swiveling) | 2 axes |

| Lateral displacement of bending head | 1 axis |

| Internal mandrel unit | Option |

| Swiveling in (spindle) | 1 axis (option) |

| Gripper tool | |

| Operating principle | Pneumatic |

| Structure | Open |

| Single stroke | 750 mm |

| Multiple stroke | At will |

| Programming | |

| Length/angle | yes |

| Coordinates | yes |

| Job order lists | yes |

| Graphical display | yes |

| Automation | |

| Loading from a magazine | Option |

| Position-oriented discharge | Option |

| Combination with robots | Option |

| Weight | 1,300 kg |

| Space requirements | 2,100 x 1,250 x 2,050 (lxwxh in mm) |

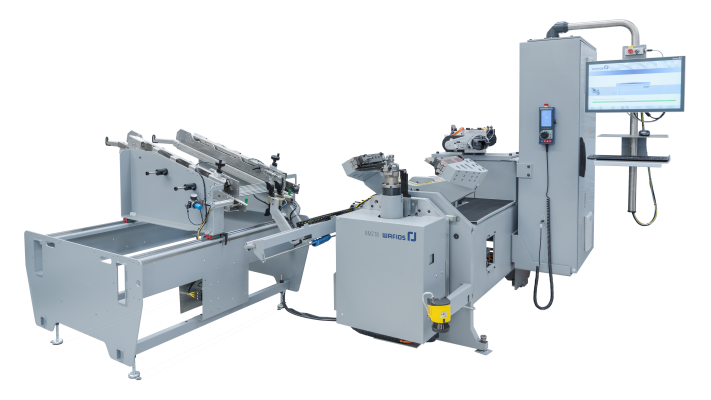

BMZ 18

- The tool's rotary axes and the backstop unit enable a high operating speed and short bending times

- Less collapsing of the bend, improved dimensional accuracy of workpieces and repeat accuracy due to the use of a backstop unit

- Also applicable for thick-walled workpieces, e.g. injection pipes incl. connecting pieces

- As parts can be finish-bent from their opposite end, short end lengths on both ends with 1 x tube diameter are possible

- High process reliability in series production

- Automatic loading and unloading (option)

- Right/left bending in one clamping