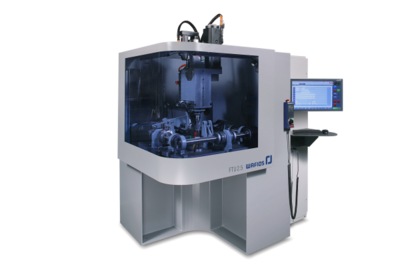

Powerful, dynamic and versatile machines for the production of all types of torsion springs. The FMU+ and FTU series are characterised by high reliability with simple operation. With a wide range of equipment features that can be adapted to specific requirements, WAFIOS torsion spring machines are ideal for the universal production of torsion springs.

Flexible - Powerful - Reliable

Machine comparison FTU Series

- Significant increase in performance ensures optimized unit costs, especially in large-volume production

- Maximum quality and repeatability thanks to optimized rigid machine concept

- Application possibilities are more flexible and set-up times are shorter due to WAFIOS WPS 3.2 EasyCam

- High compatibility with existing sets of tools from the FTU series

- Upgraded version with insulation stripping device for the production of inductor coils can be used (option)

Please select wire diameter [mm]

FTU 1.5

from 0.3

to 2 mm

| Spring steel wire Ø | 0.2 - 1 mm |

| Enameled copper wire Ø | 0.3 - 2 mm |

| Color detection device | 0 - 0 |

| Height of spring body / copper coil body | max. 90 mm |

| Diameter of winding mandrel | d, max. 15 mm |

| Length of the peripheral first spring leg | max. 50 mm |

| Output, depending on spring shape, up to | 200 pcs./min: |

FTU 2.5

from 1

to 4 mm

| Spring steel wire Ø | 0.5 - 2.2 mm |

| Enameled copper wire Ø | 1 - 4 mm |

| Height of spring body / copper coil body | max. 120 mm |

| Diameter of winding mandrel | d, max. 25 mm |

| Length of the peripheral first spring leg | max. 120 mm |

| Output, depending on spring shape, up to | 120 springs/min |

FTU 1.5

Further information