Series Production of Enameled Copper Coils

Enameled copper coils are used for interference suppression chokes and inductors in the automotive and electrical industries, for example.

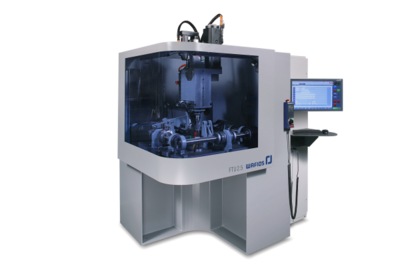

The bending and winding machines in the FTU series, designed for producing enameled copper coils, deliver outstanding performance that optimizes unit costs in large-scale manufacturing. The innovative WPS 3.2 EasyCam programming system uses fast and simple operating sequences to ensure high standards of user convenience, short set-up times, and flexible applications.

Optional equipment for automated insulation stripping and tin-plating enables reliable, repeatable production of ready-to-install coils.

Machines

Machine comparison FMU+ Series

- Production of highly complex spring geometries due to flexible machine design, e.g. production at a second station, among other things

- Numerous options for very high flexibility and user convenience

- Convenient programming of complex spring geometries with digital tools for simulation, process optimization and collision prevention.

- High quality standards ensure zero-defect production and highest machine availability

- Established, worldwide unique machine concept

Please select wire diameter [mm]

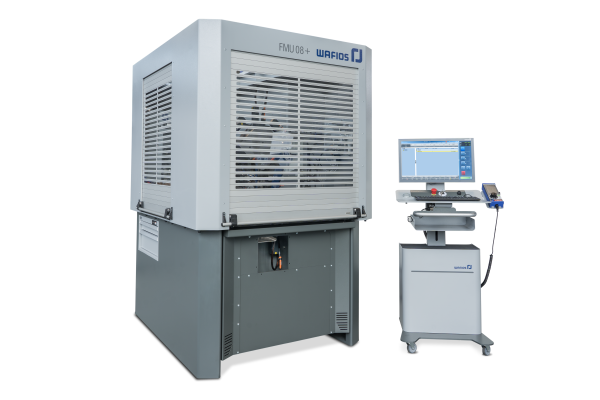

FMU 08+

from 0.2

to 0.8 mm

| Wire diameter | 0.2 - 0.8 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 120 m/min |

| Bend-back clearance | max. 25 mm |

| Stroke vertical table | +40 / - 80 mm |

| Stroke, horizontal table (option) | +/- 60 mm |

| Stroke, longitudinal table (option) | 100 mm |

| Linear unit stroke | ---- |

| Slider stroke | 34 mm |

| Upgradable to max. CNC axes | 20 |

FMU 16+

from 0.4

to 1.6 mm

| Wire diameter | 0.4 - 1.6 mm |

| according to DIN EN 10270 | |

| 1,200 N/mm² | 0.4 - 1.8 mm |

| 600 N/mm² | 0.4 - 2 mm |

| Feed speed | max. 140 m/min |

| Bend-back clearance | max. 75 mm |

| Stroke vertical table | +60 / -100 mm |

| Stroke, horizontal table (option) | +/- 80 mm |

| Stroke, longitudinal table (option) | 110 mm |

| Linear unit stroke | 320 mm |

| Output - Springs | 150 pcs./min: |

| Slider stroke | 54 mm |

| Upgradable to max. CNC axes | 24 |

FMU 20+

from 0.4

to 2 mm

| Wire diameter | 0.4 - 2 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 140 m/min |

| Bend-back clearance | max. 75 mm |

| Stroke vertical table | +60 / -100 mm |

| Stroke, horizontal table (option) | +/- 80 mm |

| Stroke, longitudinal table (option) | 110 mm |

| Linear unit stroke | 320 mm |

| Slider stroke | 54 mm |

| Upgradable to max. CNC axes | 24 |

FMU 25+

from 0.8

to 2.5 mm

| Wire diameter | 0.8 - 2.5 mm |

| according to DIN EN 10270 | |

| ISO 10270 | 1.8 - 4 mm |

| Feed speed | max. 125 m/min |

| Bend-back clearance | max. 130 mm |

| Stroke vertical table | +70 / -120 mm |

| Stroke, horizontal table (option) | +/- 90 mm |

| Stroke, longitudinal table (option) | 180 mm |

| Linear unit stroke | 400 mm |

| Slider stroke | 80 mm |

| 1,200 N/mm² | 0.8 - 2.5 mm |

| 600 N/mm² | 0.8 - 3.5 mm |

| Output - Springs | max. 100 pcs./min. |

| Upgradable to max. CNC axes | 24 |

FMU 32+

from 0.8

to 3.2 mm

| Wire diameter | 0.8 - 3.2 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 125 m/min |

| Bend-back clearance | max. 130 mm |

| Stroke vertical table | +70 / -120 mm |

| Stroke, horizontal table (option) | +/- 90 mm |

| Stroke, longitudinal table (option) | 180 mm |

| Linear unit stroke | 400 |

| Slider stroke | 95 mm |

| Upgradable to max. CNC axes | 24 |

FMU 40+

from 1.8

to 4 mm

| Wire diameter | 1.8 - 4 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 80 m/min |

| Bend-back clearance | max. 200 mm |

| Stroke vertical table | +55 / -175 mm |

| Stroke, horizontal table (option) | +/- 70 mm |

| Stroke, axial table (option) | 260 mm |

| Linear unit stroke | 750 mm |

| Slider stroke | 130 mm |

| Upgradable to max. CNC axes | 24 |

FMU 50+

from 1.8

to 5

| Wire diameter | 1.8 - 5 |

| according to DIN EN 10270 | |

| Feed speed | max. 80 m/min |

| Bend-back clearance | max. 200 mm |

| Stroke vertical table | +55 / -175 mm |

| Stroke, horizontal table (option) | +/- 70 mm |

| Stroke, axial table (option) | 260 mm |

| Linear unit stroke | 750 mm |

| Slider stroke | 130 mm |

| Upgradable to max. CNC axes | 24 |

FMU 65+

from 2.8

to 6.5 mm

| Wire diameter | 2.8 - 6.5 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 70 m/min |

| Bending moment | 27 Nm |

| Bend-back clearance | max. 320 mm |

| Stroke vertical table | +55 / -175 mm |

| Stroke, horizontal table (option) | +/- 100 mm |

| Stroke, axial table (option) | 340 mm |

| Linear unit stroke | ---- |

| Slider stroke | 200 mm |

| Output - Springs | max. 80 pcs./min |

| Upgradable to max. CNC axes | 24 |

FMU 80+

from 2.8

to 8 mm

| Wire diameter | 2.8 - 8 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 70 m/min |

| Bending moment | 128 Nm |

| Bend-back clearance | max. 320 mm |

| Stroke vertical table | +55 / -175 mm |

| Stroke, horizontal table (option) | +/- 100 mm |

| Stroke, axial table (option) | 340 mm |

| Linear unit stroke | ---- |

| Output - Springs | max. 50 pcs./min. |

| Slider stroke | 200 mm |

| Upgradable to max. CNC axes | 24 |

FMU 100+

from 4

to 10 mm

| Wire diameter | 4 - 10 mm |

| according to DIN EN 10270 | |

| Feed speed | max. 65 m/min |

| Bend-back clearance | max. 320 mm |

| Stroke vertical table | +55 / -175 mm |

| Stroke, horizontal table (option) | +/- 100 |

| Stroke, axial table (option) | ---- |

| Linear unit stroke | ---- |

| Slider stroke | 200 mm |

| Upgradable to max. CNC axes | 24 |

FMU 08+

- Numerous options for very high flexibility and user convenience

- Convenient programming of complex spring geometries

- High quality standards ensure zero-defect production

- High machine availability

Further information