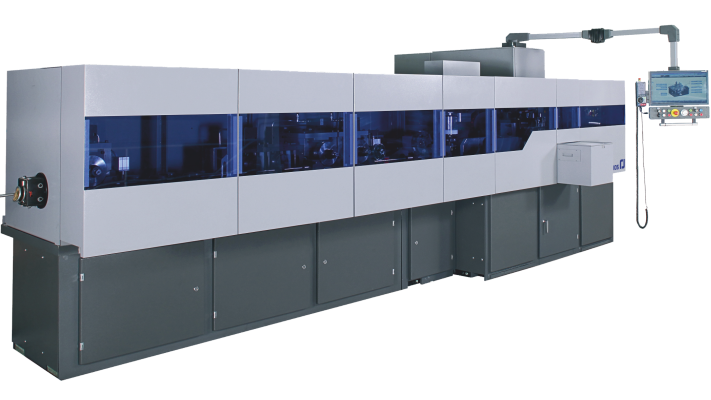

Machine comparison KEB Series

- High-end machines for the production of high-strength chains in continuous operation

- Output is increased by 10% (KEB x.2)

- Dimensionally accurate chain with tightest bending tolerances evenly bent in continuous operation

- Robust machine design for the production of high-strength chains over a long period of time

- Safety devices for protecting machine parts and tools

High-end cold-forming process for high-strength chains - KEB and KER series

Chain bending machines of the KEB and KER series are used to cold-bend round steel link chains. Wire material is fed in from the wire coil. The bent chain link can then immediately be electrically welded on a separate machine.

Please select wire diameter [mm]

KEB 3.1

from 2

to 6.5 mm

| Wire diameter | 2 - 6.5 mm |

| at max. 750 N/mm² | 2 - 6.5 mm |

| at max. 500 N/mm² | 2 - 6.5 mm |

| Wire feed length | max. 120 mm |

| Inner link length (pitch) | max. 42 mm |

| Output, chain links | 120 - 150 pcs./min |

KEB 4.1

from 4

to 10 mm

| Wire diameter | 4 - 10 mm |

| at max. 750 N/mm² | 4 - 10 mm |

| at max. 500 N/mm² | 4 - 11 mm |

| Wire feed length | max. 200 mm |

| Inner link length (pitch) | max. 66 mm |

| Output, chain links | 65 - 90 pcs./min |

KEB 4.2

from 5

to 10 mm

| Wire diameter | 5 - 10 mm |

| at max. 1,000 N/mm² | 5 - 9 mm |

| at max. 900 N/mm² | 5 - 10 mm |

| Wire feed length | max. 155 mm |

| Inner link length (pitch) | 14.5 - 52 mm |

| Output, chain links | 60 - 75 pcs./min |

KEB 5.1

from 6

to 14 mm

| Wire diameter | 6 - 14 mm |

| at max. 750 N/mm² | 6 - 13 mm |

| at max. 500 N/mm² | 6 - 14 mm |

| Wire feed length | max. 240 mm |

| Inner link length (pitch) | max. 82 mm |

| Output, chain links | 55 - 80 pcs./min |

KEB 7.2

from 10

to 18 mm

| Wire diameter | 10 - 18 mm |

| at max. 1,000 N/mm² | 10 - 16 mm |

| at max. 800 N/mm² | 10 - 18 mm |

| Wire feed length | max. 280 mm |

| Inner link length (pitch) | 29 - 95 mm |

| Output, chain links | 35 - 45 pcs./min |

KEB 8.1

from 12

to 23 mm

| Wire diameter | 12 - 23 mm |

| at max. 750 N/mm² | 12 - 20 mm |

| at max. 500 N/mm² | 12 - 23 mm |

| Wire feed length | max. 340 mm |

| Inner link length (pitch) | max. 100 mm |

| Output, chain links | 15 - 25 pcs./min |

KEB 7.2

- Machine efficiency increased by ca.10% (KEB 7.2)

- Robust machine design for the production of high-strength chains over a long period of time

- Wire can be inserted into the machine by means of the first pair of feed rollers

- Repeatable machine settings by saving set-up parameters, thus shorter set-up and tooling times

Options

- Wire embossing device

- Wetting device

- Hydraulic, quick-release mechanism for straightening devices of the KEB 7.2

More output, higher tensile strength and increased availability - KEB x.2 series

Modern design with increased safety and operating convenience. Adjustment of operating ranges and tensile wire strengths to current market requirements, including stainless steel and adjusted to the chain welding machines of the x.2 series. Replacing the complicated mechanical system of control shafts with individual servodrives reduces tooling and set-up times because there is no mechanical set-up work required anymore and parameters can be saved for later use in the control system.