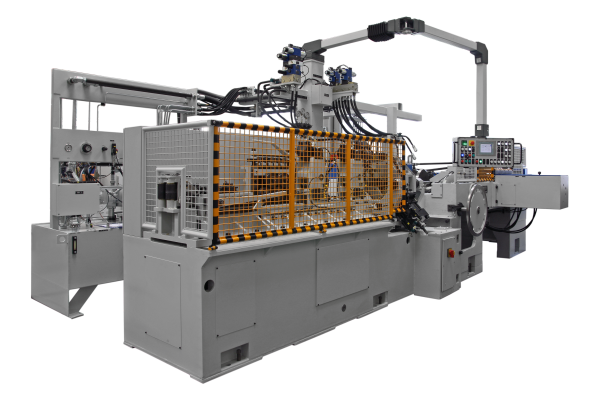

Machine comparison KEB Series

- High-end machines for the production of high-strength chains in continuous operation

- Output is increased by 10% (KEB x.2)

- Dimensionally accurate chain with tightest bending tolerances evenly bent in continuous operation

- Robust machine design for the production of high-strength chains over a long period of time

- Safety devices for protecting machine parts and tools

High-end cold-forming process for high-strength chains - KEB and KER series

Chain bending machines of the KEB and KER series are used to cold-bend round steel link chains. Wire material is fed in from the wire coil. The bent chain link can then immediately be electrically welded on a separate machine.

Please select wire diameter [mm]

KEB 3.1

from 2

to 6.5 mm

| Wire diameter | 2 - 6.5 mm |

| at max. 750 N/mm² | 2 - 6.5 mm |

| at max. 500 N/mm² | 2 - 6.5 mm |

| Wire feed length | max. 120 mm |

| Inner link length (pitch) | max. 42 mm |

| Output, chain links | 120 - 150 pcs./min |

KEB 4.1

from 4

to 10 mm

| Wire diameter | 4 - 10 mm |

| at max. 750 N/mm² | 4 - 10 mm |

| at max. 500 N/mm² | 4 - 11 mm |

| Wire feed length | max. 200 mm |

| Inner link length (pitch) | max. 66 mm |

| Output, chain links | 65 - 90 pcs./min |

KEB 4.2

from 5

to 10 mm

| Wire diameter | 5 - 10 mm |

| at max. 1,000 N/mm² | 5 - 9 mm |

| at max. 900 N/mm² | 5 - 10 mm |

| Wire feed length | max. 155 mm |

| Inner link length (pitch) | 14.5 - 52 mm |

| Output, chain links | 60 - 75 pcs./min |

KEB 5.1

from 6

to 14 mm

| Wire diameter | 6 - 14 mm |

| at max. 750 N/mm² | 6 - 13 mm |

| at max. 500 N/mm² | 6 - 14 mm |

| Wire feed length | max. 240 mm |

| Inner link length (pitch) | max. 82 mm |

| Output, chain links | 55 - 80 pcs./min |

KEB 7.2

from 10

to 18 mm

| Wire diameter | 10 - 18 mm |

| at max. 1,000 N/mm² | 10 - 16 mm |

| at max. 800 N/mm² | 10 - 18 mm |

| Wire feed length | max. 280 mm |

| Inner link length (pitch) | 29 - 95 mm |

| Output, chain links | 35 - 45 pcs./min |

KEB 8.1

from 12

to 23 mm

| Wire diameter | 12 - 23 mm |

| at max. 750 N/mm² | 12 - 20 mm |

| at max. 500 N/mm² | 12 - 23 mm |

| Wire feed length | max. 340 mm |

| Inner link length (pitch) | max. 100 mm |

| Output, chain links | 15 - 25 pcs./min |

KEB 8.1

- 3-shaft system

- Smooth machine running

- Operations (forward and backward stroke) are positively controlled via cams

- Safety devices for wire feed, chain link blank stop, gripping at the bending mandrel

- Quickly responding clutch and brake combination

- The clamping tools of the wire feed are pneumatically actuated. (KEB 3.1 - KEB 5.1) All other motion sequences are mechanically controlled

- Wire feed and gripping, notching, and closing the tilting tongs occurs hydraulically. (KEB 8.1) All other motion sequences are mechanically controlled