Our range of spring coiling machines can accommodate every requirement, from tiny compression springs with wire diameters measuring as little as 0.12 mm right through to the other end of the scale at up to 30 mm.

Fast - Flexible - Productive

Machines

Machine comparison FUL Series

- High output, high flexibility

- Future-oriented machine concept, individual configuration for all kinds of application

- Convenient programming system WPS 3.2 EasyWay increases machine availability

- High quality standards ensure zero-defect production

- iQ Functions - Enhanced efficiency through intelligent process control

Please select wire diameter [mm]

FUL 16+

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm=2600 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 260 m/min |

FUL 26+

from 0.2

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

FUL26+ 4speed

from 0.5

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

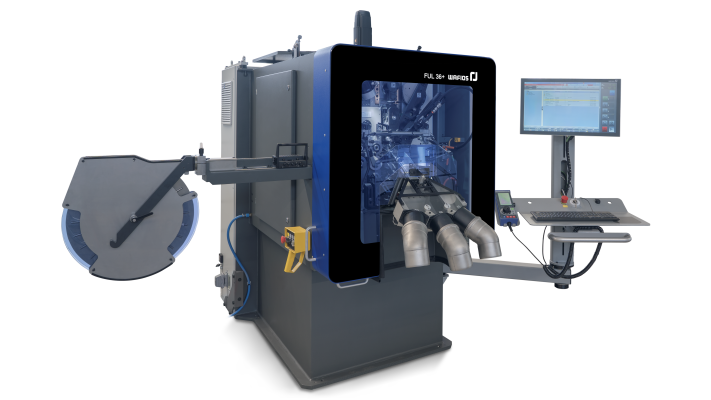

FUL 36+

from 0.5

to 3 mm

| Wire diameter | 0.5 - 3 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 220 m/min |

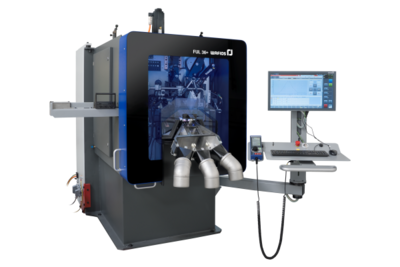

FUL36+ 4speed

from 1

to 2.8 mm

| Wire diameter | 1 - 2.8 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 500 m/min |

FUL 46

from 0.9

to 4.5 mm

| Wire diameter | 0.9 - 4.5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Left, right as option |

| Feed speed | max. 175 m/min |

FUL56

from 1.5

to 5 mm

| Wire diameter | 1.5 - 5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 150 m/min |

FUL 76

from 2.1

to 7.5 mm

| Wire diameter | 2.1 - 7.5 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 140 mm |

| Coiling direction | right and left |

| Feed speed | max. 130 m/min |

FUL 86

from 3.1

to 8 mm

| Wire diameter | 3.1 - 8 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 150 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 130 m/min |

FUL 126

from 5.1

to 12 mm

| Wire diameter | 5.1 - 12 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 220 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 100 m/min |

FUL 166

from 6.1

to 16 mm

| Wire diameter | 6.1 - 16 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 175

from 6.1

to 17 mm

| Wire diameter | 6.1 - 17 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 183

from 8.1

to 18 mm

| Wire diameter | 8.1 - 18 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

FUL 203

from 8.1

to 20 mm

| Wire diameter | 8.1 - 20 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 65 m/min |

FUL 226

from 12.1

to 30 mm

| Wire diameter | 12.1 - 30 mm |

| Wire strength | Rm = 800 N/mm² |

| Wire diameter | 12.1 - 22 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Outer spring diameter | max. 300 mm |

| Spring index | ≥4 |

| Coiling direction | Right, left as option |

| Feed speed | max. 65 m/min |

FUL36+ 4speed

- Maximum dynamics due to new water-cooled drive technology, for an increased output and reduced unit costs

- Pay-off units in the AHT and AHP series, featuring an increased load-bearing capacity and designed for wire feed speeds of up to 500 m/min, reliably process wire from coils and spools.

- The wire buffer box compensates for fluctuations between the wire coiling machine in start/stop operation and the pay-off unit in continuous operation. The wire enters the connected machine free from tension.

- Innovative and modern machine design with enhanced ergonomics