CNC Bending Machines Specifically for Flat Wire

Producing modern drive technologies of the kind used in hybrid and electric vehicles requires new components that can be manufactured economically. Conductive components (busbars) are of particular importance in this case. They are needed to ensure safe and reliable power transmission between individual battery modules and the electric motors.

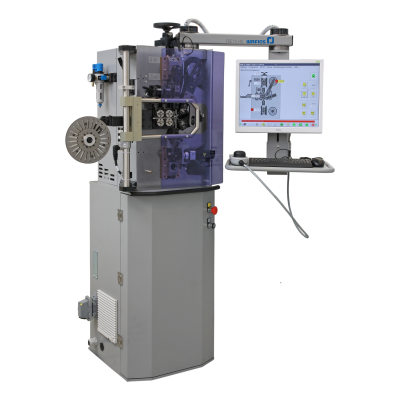

With the CNC-controlled BMF 60, WAFIOS has developed a completely new bending machine for the production of profiled parts and busbars. State-of-the-art patent-pending technologies have been incorporated in order to bend complex parts with the tightest of radii and distortions. The process steps involved are bending, cutting, insulation stripping, and twisting.

Machines

Machine comparison FSE & F Series

- Modular, customized equipment options

- Reduced costs due to modular design, energy efficiency and optimized tooling times

- Machine takes up little space, enabling optimum factory planning and plant logistics

- Economic output due to high availability

- Flexibility thanks to space-saving machine concept

Please select wire diameter [mm]

F 08

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 6 or Rm max. 2,600 N/mm² | 0.12 - 0.6 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.6 - 0.8 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 160 m/min |

F 12

from 0.2

to 1.2 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,500 N/mm² | 0.2 - 1.1 mm |

| Wire diameter at Wm 5 or Rm max. 1,800 N/mm² | 1.1 - 1.2 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 160 m/min |

F 18

from 0.35

to 1.8 mm

| Wire diameter | 0.35 - 1.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.35 - 1.6 mm |

| Wire diameter at Wm 4 or Rm max. 1,900 N/mm² | 1.6 - 1.8 mm |

| Outer spring diameter | max. 40 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 140 m/min |

FSE 15

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm = 2,600 N/mm² |

| Spring index | ≥ 4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 150 m/min |

FSE 143

from 6.1

to 14 mm

| Wire diameter | 6.1 - 14 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

F 30

from 0.7

to 3 mm

| Wire diameter | 0.7 - 3 mm |

| Wire diameter at Wm 4 or Rm max. 2,000 N/mm² | 0.7 - 2.5 mm |

| Wire diameter at Wm 6 or Rm max. 1,800 N/mm² | 2.5 - 3 mm |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 135 m/min |

F 4

from 1.5

to 4.5 mm

| Wire diameter | 1.5 - 4.5 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 1.5 - 4 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 1.5 - 4.5 mm |

| Outer spring diameter | max. 100 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

F 6

from 2.6

to 7 mm

| Wire diameter | 2.6 - 7 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 2.1 - 6 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 2.1 - 7 mm |

| Outer spring diameter | max. 130 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

FSE 15

- Fully fledged compression spring coiler as standard version, modular expansion options

- Optimum unit costs in compression spring production

- High availability thanks to reliable and proven machine control plus easy-to-maintain design

- High-performance development with extended range of applications

- Precision thanks to the latest measuring and control technology

- Shorter set-up time and greater operating convenience

Further information