Our grinding machines offer you proven technology in perfect combination with infinitely variable cutting speed, fully automatic dressing, laser-controlled grinding wheel wear compensation, spring length measurement and high-quality control with automatic programme generation. In addition, there is an extensive options package and various interfaces for communication with peripheral devices, automation solutions and entry into the world of Industry 4.0.

Powerful - Safe - Precise

Maschinen

Machine comparison FSE & F Series

- Modular, customized equipment options

- Reduced costs due to modular design, energy efficiency and optimized tooling times

- Machine takes up little space, enabling optimum factory planning and plant logistics

- Economic output due to high availability

- Flexibility thanks to space-saving machine concept

Please select wire diameter [mm]

F 08

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 6 or Rm max. 2,600 N/mm² | 0.12 - 0.6 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.6 - 0.8 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 160 m/min |

F 12

from 0.2

to 1.2 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,500 N/mm² | 0.2 - 1.1 mm |

| Wire diameter at Wm 5 or Rm max. 1,800 N/mm² | 1.1 - 1.2 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 160 m/min |

F 18

from 0.35

to 1.8 mm

| Wire diameter | 0.35 - 1.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.35 - 1.6 mm |

| Wire diameter at Wm 4 or Rm max. 1,900 N/mm² | 1.6 - 1.8 mm |

| Outer spring diameter | max. 40 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 140 m/min |

FSE 143

from 6.1

to 14 mm

| Wire diameter | 6.1 - 14 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

F 30

from 0.7

to 3 mm

| Wire diameter | 0.7 - 3 mm |

| Wire diameter at Wm 4 or Rm max. 2,000 N/mm² | 0.7 - 2.5 mm |

| Wire diameter at Wm 6 or Rm max. 1,800 N/mm² | 2.5 - 3 mm |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 135 m/min |

F 4

from 1.5

to 4.5 mm

| Wire diameter | 1.5 - 4.5 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 1.5 - 4 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 1.5 - 4.5 mm |

| Outer spring diameter | max. 100 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

F 6

from 2.6

to 7 mm

| Wire diameter | 2.6 - 7 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 2.1 - 6 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 2.1 - 7 mm |

| Outer spring diameter | max. 130 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

F 08

- Fully fledged compression spring coiler as standard version, modular expansion options

- Optimum unit costs in compression spring production

- High availability thanks to reliable and proven machine control plus easy-to-maintain design

- High-performance development with extended range of applications

- Precision thanks to the latest measuring and control technology

- Shorter set-up time and greater operating convenience

Further information

Coiling Roller with Mounting Fixture – The Alternative to Stationary Coiling Tools

(All)

Download

(PDF, 190 KB)

Coiling Pins with PCD Insert - Processing Stainless Steel Wire Economically

(All)

Download

(PDF, 978 KB)

RE-GRINDING lohnt sich- bis zu 70% Kostenersparnis ihr Nachschleifservice für Abschneidedorne

(German)

Download

(PDF, 282 KB)

RE-GRINDING pays off - Cost savings of up to 70% Your regrinding service for cutting mandrels

(All)

Download

(PDF, 278 KB)

Drehbarer Rollendrahtführung – Optimiert für die Verarbeitung von Profildraht

(German)

Download

(PDF, 751 KB)

Coiling Roller with Mounting Fixture – The Alternative to Stationary Coiling Tools

(All)

Download

(PDF, 190 KB)

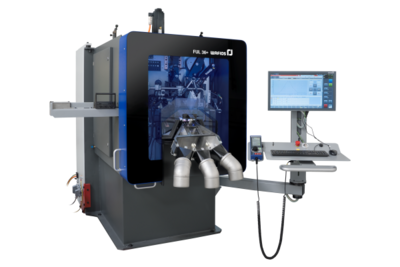

Automated Spring End Grinding Machines

With our spring end grinding machines in mind, we offer customized solutions that optimize not only the grinding process, but also loading and unloading:

- Universal, modular loading kit for springs with spring lengths L0 = 10 – 200 mm

- Ejection unit for emptying the loading plate

- Management of the feeding process

- Integration of the feeding control into the WPS 3.2 EasyWay

![[Translate to English:] Beladung einer Federendenschleifmaschine](/fileadmin/user_upload/csm_AFS_Federendenschleifen_800x600px_d08ed53958.png)